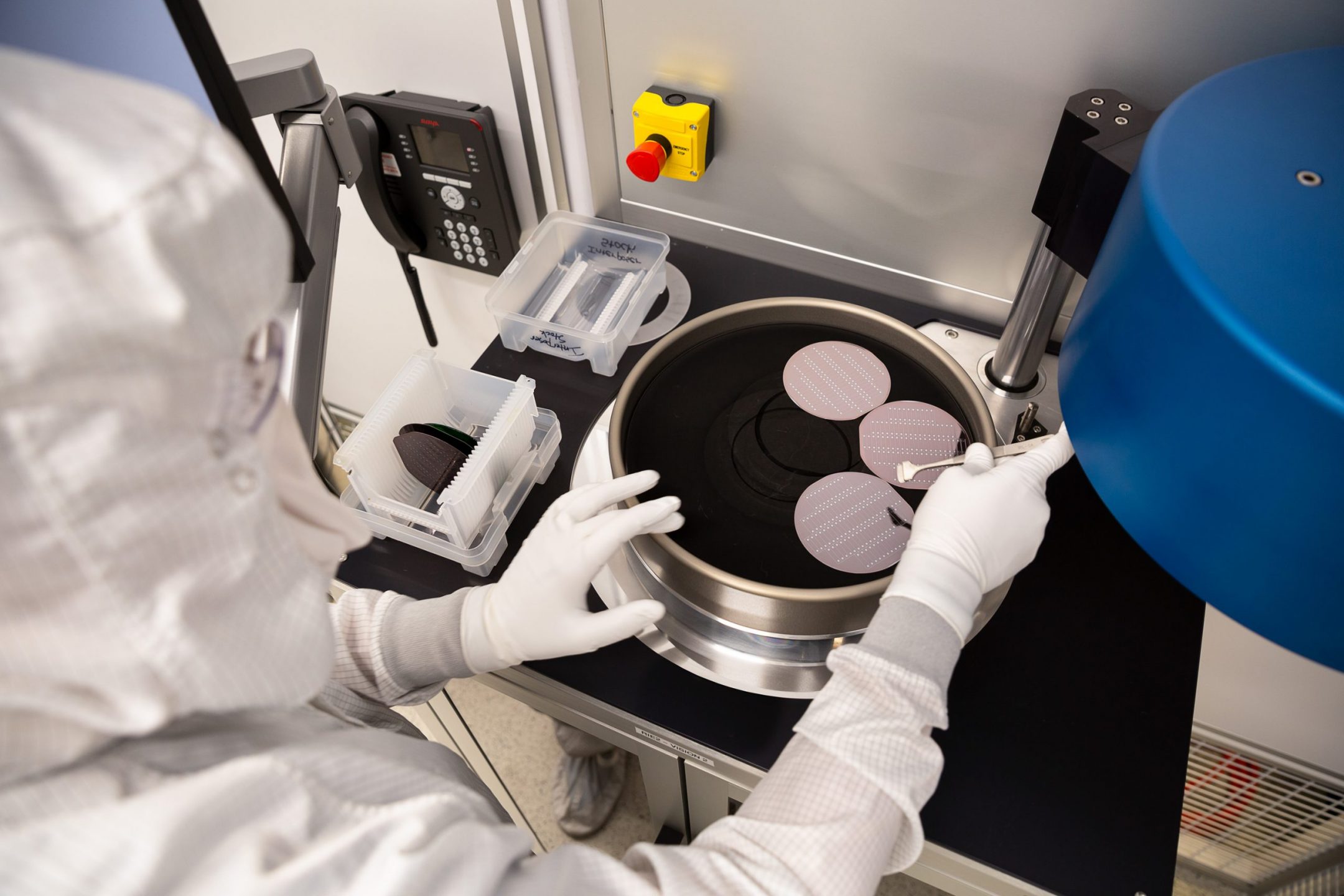

A Semiconductor Cleanroom in the Middle of a Busy University Campus

Fluke Hall Nanofabrication Facility

Hoffman supported UW’s academic research and industry partnerships with a carefully phased renovation of an occupied campus nanofabrication building.

For this complex project, Hoffman renovated 40,600 SF of UW’s four-story nanofabrication building so that it can serve as a long-term core University facility, supporting academic research and industry partnership. Fluke Hall is used by researchers and leased out to the private sector to provide revenue for the UW.

The building houses a semiconductor cleanroom plus mechanical penthouses; Hoffman also upgraded the mechanical and electrical infrastructure.

Challenge

Keep the building occupied and online during construction to prevent the University from losing revenue.

Solution

Hoffman developed a three-phase construction approach that kept the existing cleanroom online throughout the upgrade. We used temporary workarounds during each phase to allow the University to continue to use areas of the building.

Minimizing Disruption

Construction sequencing and coordination expertise was critical to minimizing campus disruption.

To allow the building to remain occupied during construction and prevent the university from losing revenue, Hoffman kept the existing cleanroom online throughout the upgrade by working in three phases. Hoffman developed temporary workarounds during construction of each phase to allow the University to continue to use areas of the building.