A Culture of Innovation and Continuous Improvement

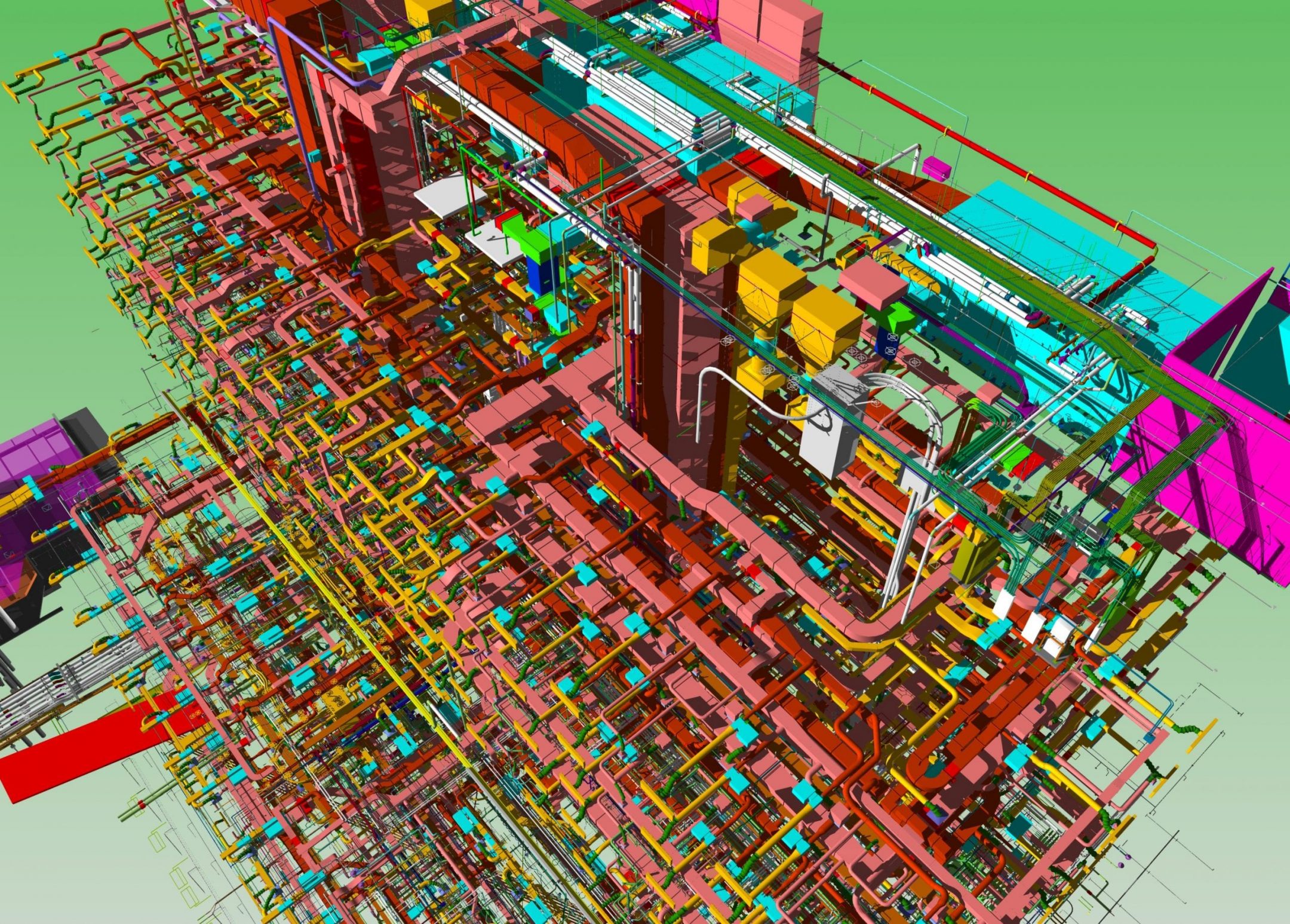

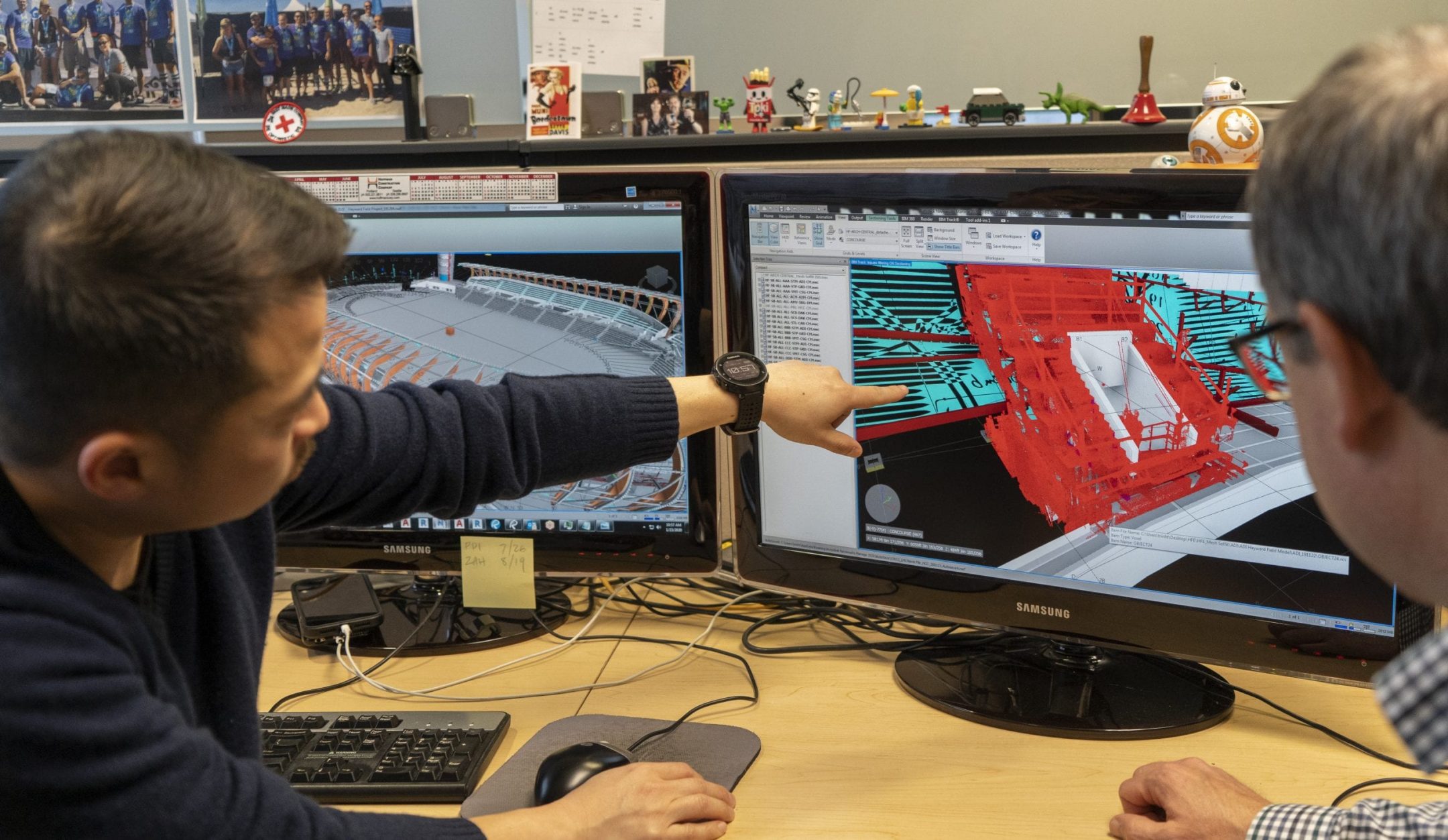

Hoffman is implementing Building Information Modeling and Virtual Design and Construction on every project to help teams coordinate and control projects down to the smallest detail. BIM allows complex projects to be completed in a common digital environment, with seamless integration from the architect’s sketch to the fabricator’s shop drawings, tied in real time to the contractor’s schedule and the owner’s budget. Hoffman’s expertise with BIM goes beyond the typical role of coordinating between the design team and the subcontractors.

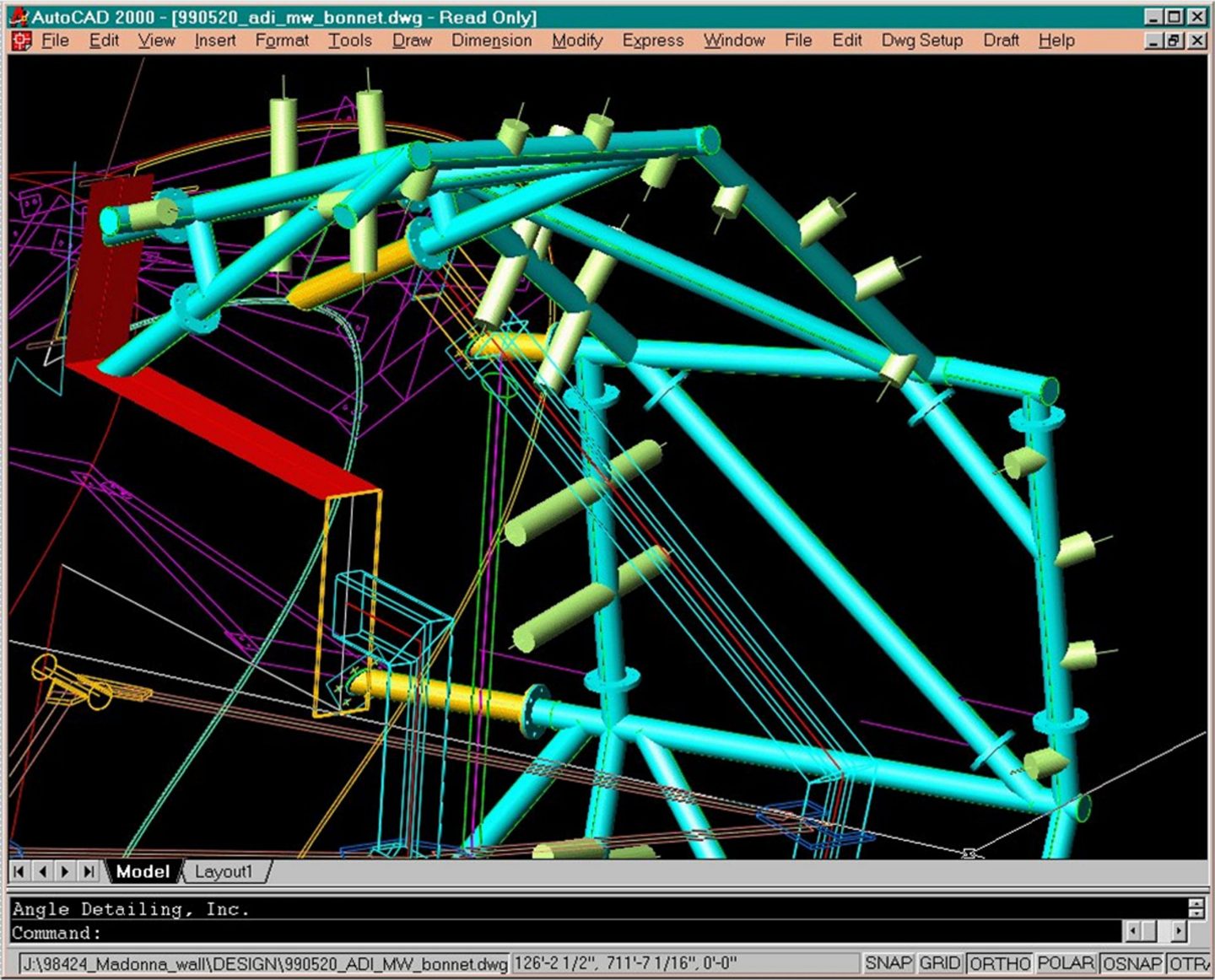

Case Study: Pushing Aerospace Software Past Its Limits at MoPOP

On MoPOP, the use of CATIA, a sophisticated 3D computer modeling program, was crucial in creating the geometric data needed by fabricators and subcontractors to manufacture and install EMP’s complex, asymmetrical elements.

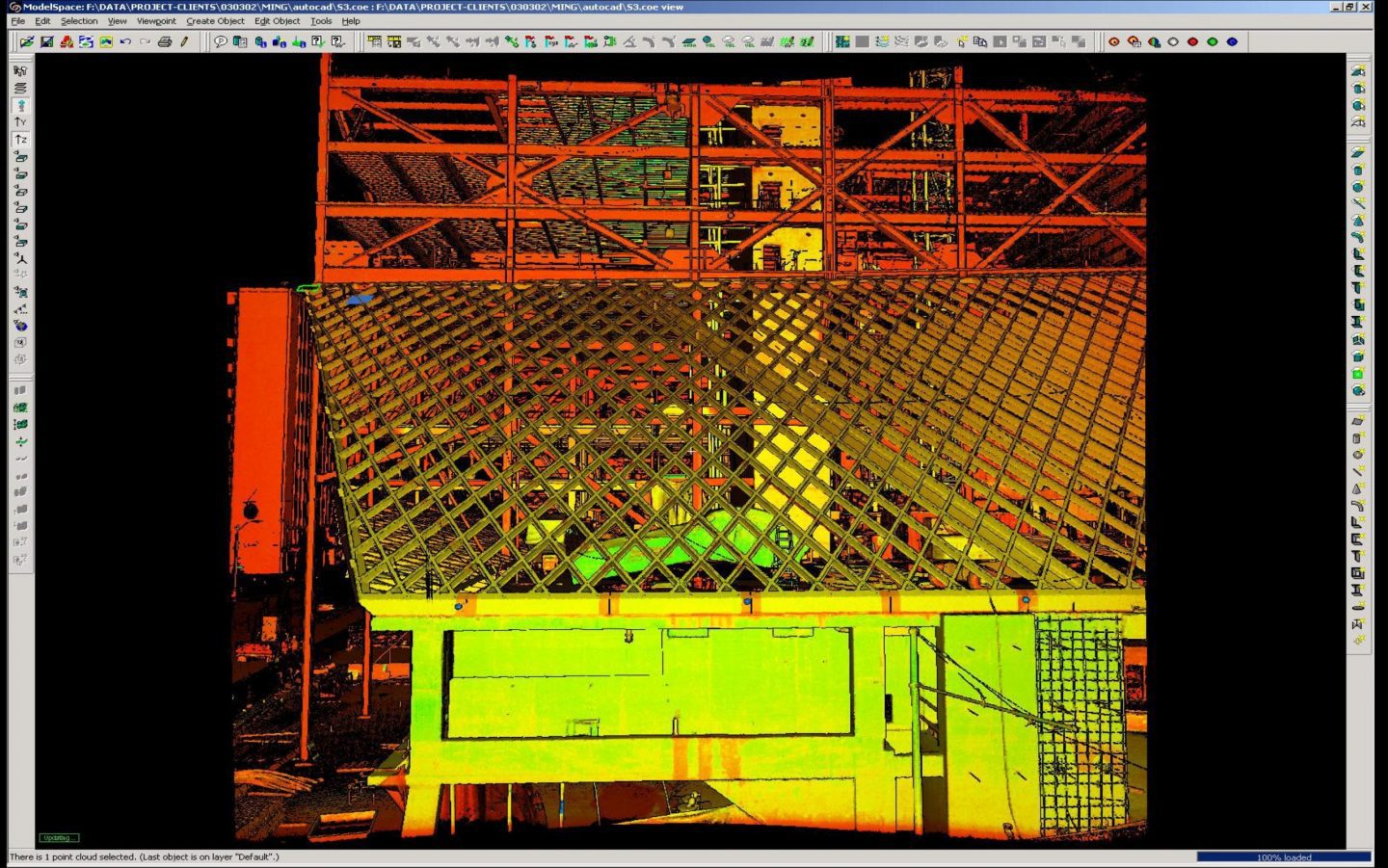

Hoffman Delivers: Laser Scanning

3D laser scanning is a key step in performing complex renovations and integrating with existing buildings. These scans can be combined with 3D CAD models of the structure to assure that new systems are installed without conflict.

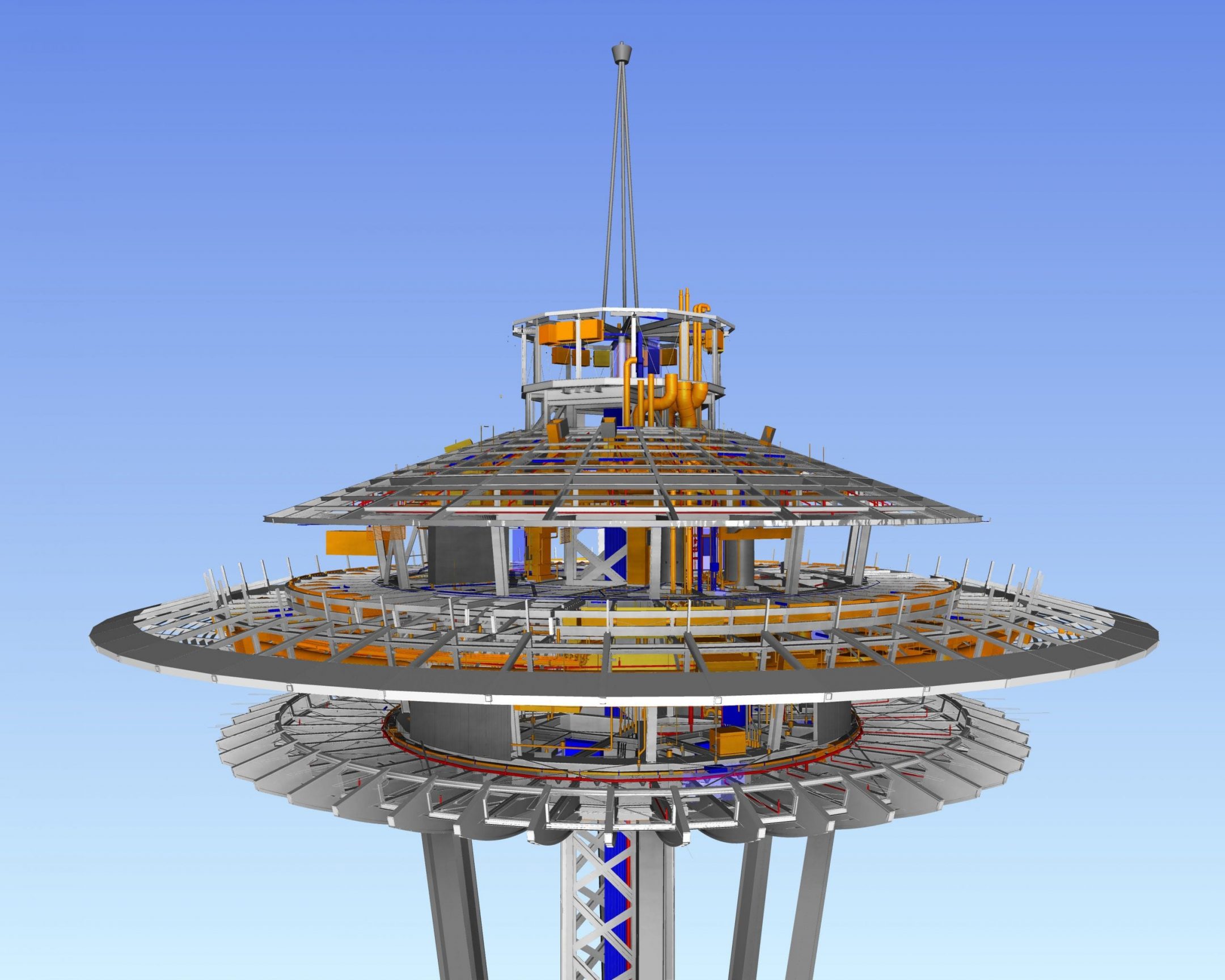

Case Study: Utilizing VDC to Execute Ambitious Design Goals at Seattle Central Library

Following EMP, Hoffman took on the challenge of the Seattle Central Library designed by Rem Koolhaas. Again, implementing a 3D CAD environment that formed the basis of a collaboration effort with key subcontractors and fabricators was instrumental in the successful completion of this world-class building.

Hoffman Delivers: Photogrammetry

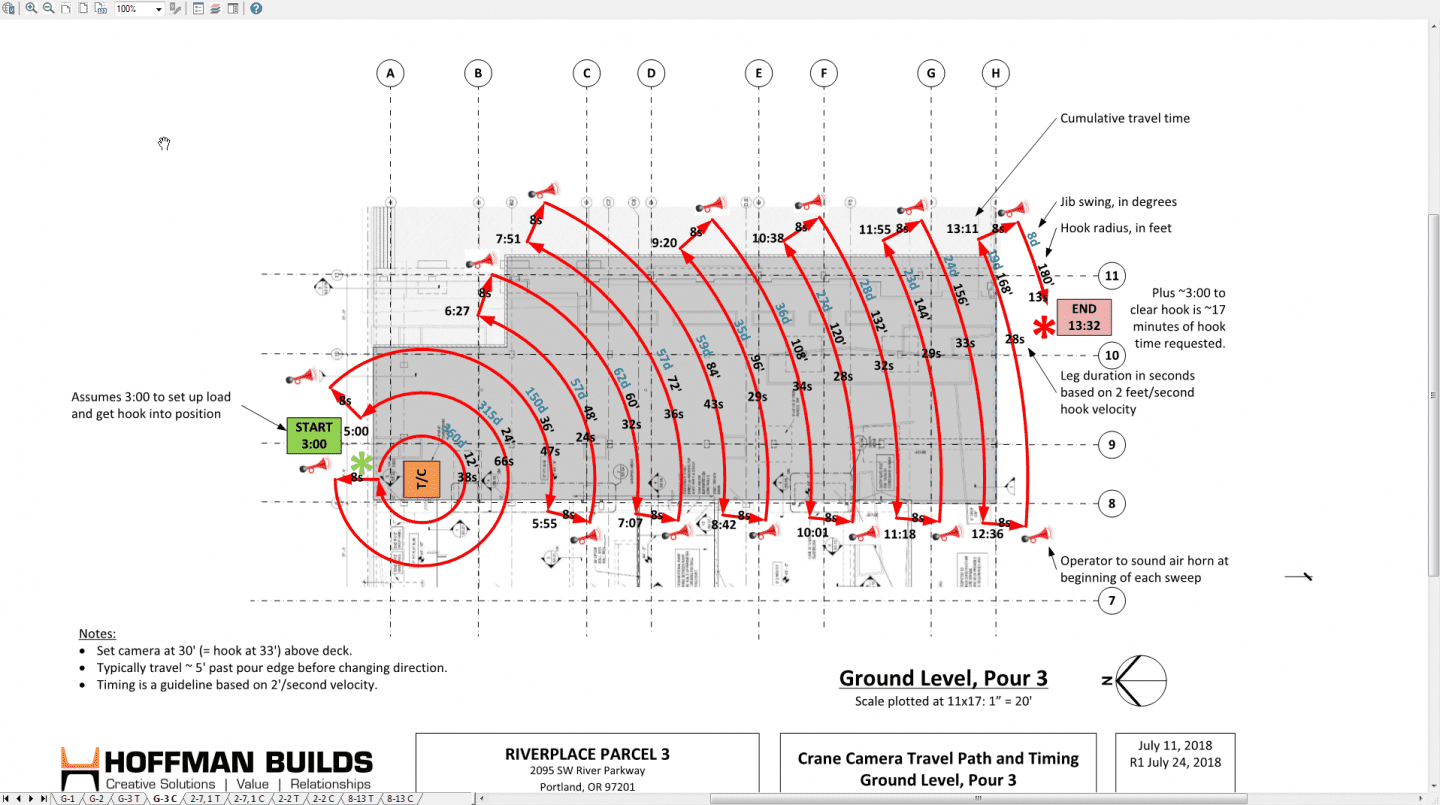

As part of a push for continuous improvement, Hoffman analyzes the challenges and “pain points” after each project, and looks for ways to solve them on future projects. We found it was challenging and expensive to scan concrete slabs to make sure the penetrations did not hit any of the post-tension cables or conduit. We thought there had to be a better way to coordinate this type of work.

Hoffman developed an in-house Low-Altitude Mapping Platform (LAMP) that allows us to quickly scan entire decks with a crane-based camera system. That system uses cloud-based photogrammetry to automatically build a 3D model of the PT cables, conduit, and rebar, which can be aligned with the project drawings. This eliminates the need for expensive and time-consuming X-ray scanning.

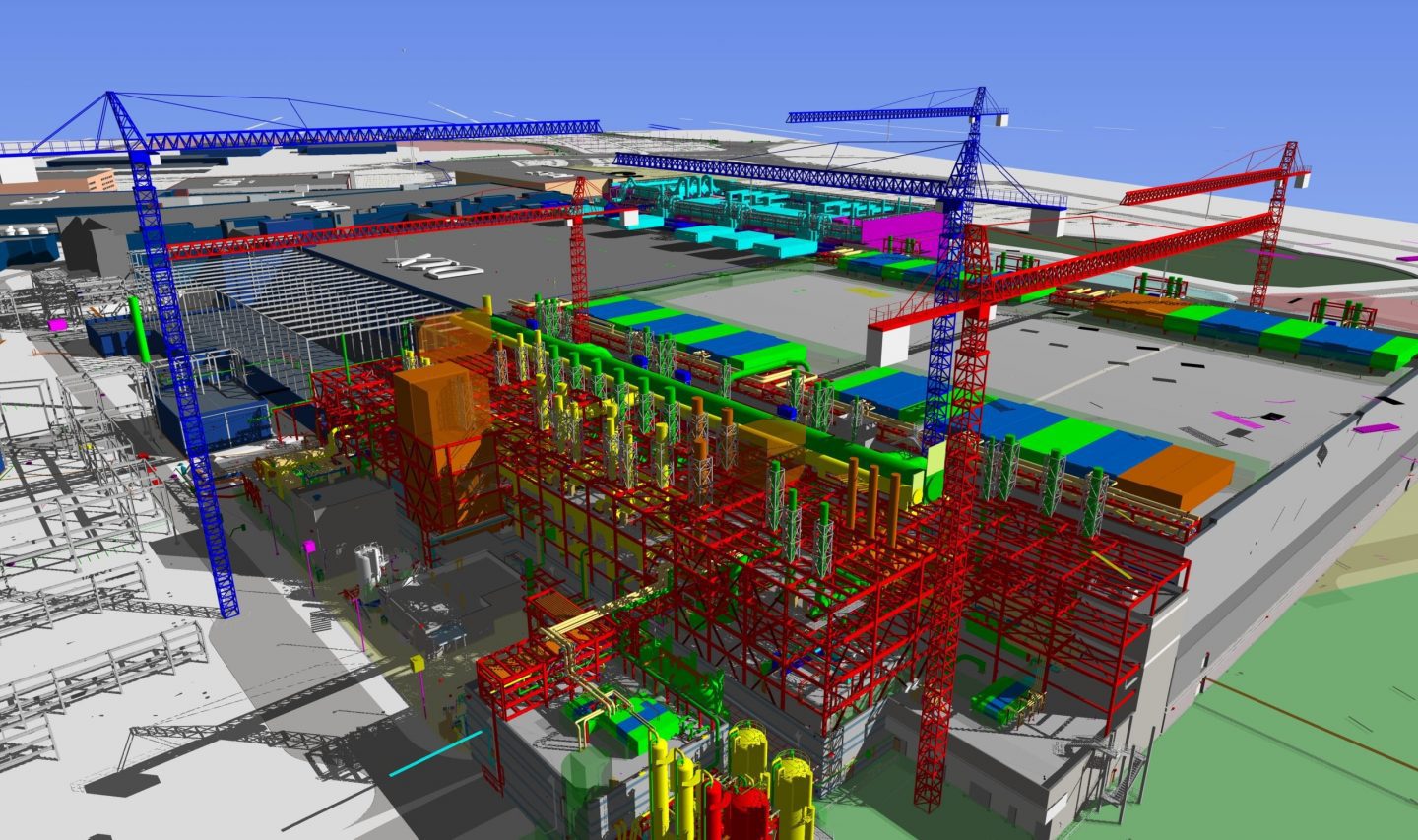

Case Study: Unparalleled BIM Workflows to Deliver the Most Complicated Buildings in the World

Hoffman is a leader in developing world-class BIM workflows on highly complex research and fabrication facility projects. Our approach to managing and coordinating model files has become the standard for many clients. For Fabs D1X Mod 1, D1X Mod 2, and Fab 42, each a 1 million+ SF microprocessor manufacturing facility, Hoffman processed over 1 million CAD files in total. Each fab was delivered on budget and on an aggressive schedule, which Hoffman accomplished due to a full utilization of BIM.

Hoffman Delivers: 4D Scheduling

We integrate the schedule with the model to ensure that the planned sequence is constructible and sound, and to take advantages of opportunities which may become apparent through this visualization process.

4D scheduling has been a critical component of the Colman Dock project, allowing our project team to safely plan and phase the work.

Get in Touch

Hoffman’s seasoned BIM team members routinely speak on topics ranging from workflows and planning to prefabrication and trade partner integration.

For speaking engagements and media inquiries, please contact:

Phil Bergsieker

BIM & VDC Director

phil-bergsieker@hoffmancorp.com