A Massive Public Works Project Protects Public Health and the Environment

Brightwater Treatment Plant

Hoffman has helped re-make the typical image of a wastewater plant into an enhancement to its community, with advanced treatment technology, elegant design, and public amenities. This massive water treatment plant project was built to serve portions of King and Snohomish counties.

The Brightwater Treatment Facility supports King County’s mission of protecting public health and the environment. The facilities we built include headworks, grit removal, primary sedimentation and aeration, as well as a new membrane technology system.

Challenge

How did Hoffman effectively manage a 120-acre jobsite, coordinating with several other general contractors performing separate scopes of work on the site, all while delivering the project $30M under budget?

Solution

This massive project was in preconstruction for two years before construction. Hoffman developed detailed phasing plans and employed as many as four tower cranes to streamline material handling and minimize impacts to other contractors.

-

2013 Build Washington Awards Project of the Year in Heavy/Industrial Category — Association of General Contractors

2013 Outstanding Civil Engineering Achievement Competition Finalist — American Society of Civil Engineers

2012 Outstanding Civil Engineering Achievement Award — American Society of Civil Engineers, Seattle Section

2012 Engineering Excellence, National Recognition Award — American Council of Engineering Companies

2012 Engineering Excellence Gold Award — American Council of Engineering Companies

2012 Excellence in Environmental Engineering, Honor Award — American Academy of Environmental Engineers

2012 Project Merit Award — Environmental Business Journal

2011 National Engineering Excellence Award Finalist — American Council of Engineering Companies

2011 Best Project, Civil Works/Infrastructure Category — ENR

2011 Excellence in Green Building, Legacy in Sustainable Development — King County Green Building Team

2011 Green Project of the Year — Northwest Construction Consumer Council

2011 International Tunneling Contractor of the Year — New Civil Engineer Magazine

2011 Environmental Achievement Award — NACWA

2011 Citation Award for Excellence in Civic Design — AIA Washington Council

2011 Engineering Excellence Award Wastewater and Stormwater Category — ACEC Of Washington State

2011 Water Reuse Project of the Year — Global Water Intelligence

2009 Top 10 Green Award — American Institute of Architects Seattle

Project Story

Largest Application of Membrane Technology

Brightwater is the largest application of membrane technology in the world, with the capacity to treat an average of 33 million gallons per day, with room for future expansion. We managed a 120-acre jobsite, with as many as four tower cranes in use at once.

Education Center

Hoffman built a LEED Platinum environmental education center on the site and created trails through natural areas. Membrane technology takes the place of traditional secondary clarifiers, removing more harmful bacteria and residual solids, producing higher-quality effluent.

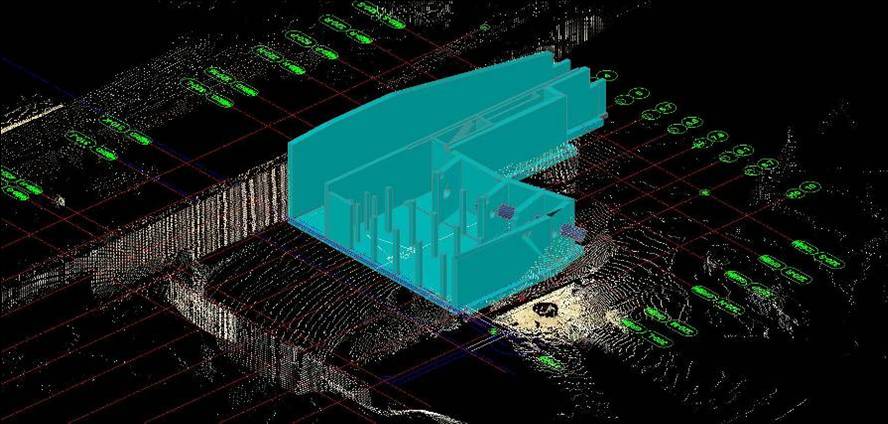

Large-Scale BIM

We were highly successful in using BIM to enhance the project, control costs, and assure the highest level of quality control. We laser scanned the site to review earthwork quantities and help balance the site for cut and fill. All the excavated material was used on-site as either foreground screening mounds or backfill for the structures, which made the earthwork sequencing a complicated shell game of moving dirt from area to area.